Case Study - Commercial

Richard Smith – Robotic Control and Automation Ltd

Richard Smith – Robotic Control and Automation Ltd

When Richard Smith invested in his first BFB RapMan back in 2009, it was going to be used for prototyping parts he would need to produce for his work before going on to make them using more traditional methods. After just a few weeks, Richard realised that while his RapMan was perfect for prototyping it was also suitable for making real parts, particularly small parts in low-volumes.

“Our most commonly-printed parts are small items such as RJ45 socket bezels and LED bezels. We can just print these out as we require in small batches.”

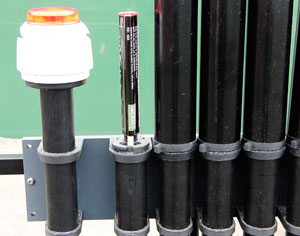

Richard works on a wide range of products. For his bird-dispersal rockets, he printed many different parts including all the brackets, bayonet connections and coupling connectors. This enabled him to get his design made quickly and tested in the field – literally!

“For one of our latest robotic projects we used our RapMan to print drive sprockets. They are 120mm diameter toothed-belt sprockets; the largest we could buy off the shelf were 100mm. If it weren’t for our RapMan this project would have cost considerably more and it would have taken another week to manufacture the components using traditional workshop methods.”

“For one of our latest robotic projects we used our RapMan to print drive sprockets. They are 120mm diameter toothed-belt sprockets; the largest we could buy off the shelf were 100mm. If it weren’t for our RapMan this project would have cost considerably more and it would have taken another week to manufacture the components using traditional workshop methods.”